Talking about what is pattern grading, It’s the process of making different-sized patterns from a master pattern based on a pattern grading chart. Grading is the process that clothing manufacturers use to make patterns for ready-to-wear clothes in a range of sizes. To grade, a pattern is to alter size at certain points to make each new pattern a different size that is bigger or smaller.

Garment pattern grading is the process of changing your garment from one size to another by hand or with a computer. Using a size pattern grading chart, without changing the original pattern.

How To Grade Patterns

Pattern grading is the process of adding to or taking away from a master pattern piece in small steps to make bigger or smaller sizes. You can start with the smallest size or the size in the middle. Pattern grading changes the overall size of a design, but it doesn’t change how it looks or what shape it has.

Pattern size construction is done with the help of grading rules that are built into computer-aided pattern grading systems. If a customer wants a different size, the manufacturer has to grade the size with letters like S, L, XL, XXL, etc.

For example, if the t-shirt design guide is 10(M), it must be made bigger to fit sizes 12(L), 14(XL), and 16(XXL) and smaller to make sizes 8(S) and 6 (XS).

Pattern grading is common in the clothing business and fashion designing industries.

Why Grading By Pattern Is Important

It’s important to keep patterns fluid. Without practice and skill, a fashion designer won’t be able to move forward. Patterns that can be changed give grading in fashion houses to make a line with a variety of designs that are similar in concept.

Types Of Garments Patterns Grading Techniques

When grading clothes, there are 2 main types of pattern grader systems.

1. Manual Pattern Grading

Marks are made at the right distances around the master pattern, and the marks are then joined together to make a larger pattern.

This makes a “pattern set,” which is a full set of templates.

-

Grading Machine

The job of making the pattern set is easier with a grading machine. The tool grabs the master or basic pattern and moves it by a precise amount in both the vertical and horizontal directions. Then, the right edge can be traced.

There are two ways to classify manual pattern grading methods today. Below, we list and briefly describe these:

- Cut And Spread

The cut-and-spread grading method starts with tracing and making marks on a white piece of paper from the original master pattern. Make sure all the marking lines can be seen here.

In this method, original patterns are cut into three pieces along the vertical axis, and the pieces are then spread out by a certain amount to grade up. Then put them on top of each other to make them smaller. For this step, you only need scissors, a pencil, a measuring tape, and a ruler.

Impress Your Clients With A Perfect Fit Across Sizes

Get Accurate & Scalable Patterns With Our Grading Expertise

Consult Now-

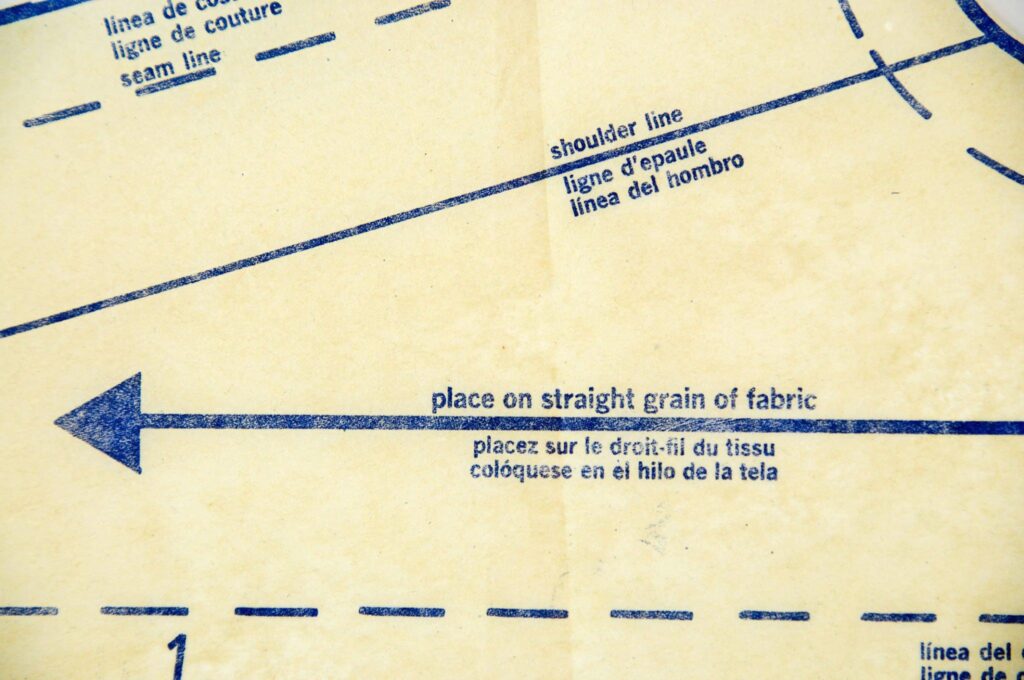

Pattern Shifting

Pattern grading also includes pattern shifting. Pattern shifting is what a pattern or fashion designer does when they want to change the size of a pattern by making it bigger or smaller. If you want to make the pattern bigger, you can copy it onto new grading sheets of paper.

To make it smaller, they will have to cut away some of the edges. To do this, you use a pattern grading ruler to move the master pattern up and down and left and right by a certain amount. The designer has redrawn the outlines to get the same result as the cut-and-spread method.

2. Computer-Aided Pattern Grading

Computed grading (CAD) is the method for grading patterns that work the fastest. But when it first came out, only bigger companies that made clothes or fashion used it in their production process. Now, CAD software costs less than it used to.

By using this method, every clothing manufacturer for small businesses quickly gets patterns that are more accurate, precise, and detailed. There are two ways that computer-based grading systems work:

- The increments for grading are put into the computer.

- The different sizes are made automatically using the same methods as when grading by hand.

The resulting nest of patterns can be shown to scale on the computer screen so that they can be looked at and, if needed, changed.

Once the computer has made the pattern set, it can be used in different ways, depending on how automated the factory is.

In a fully automated system, the parts of the clothes will be automatically sorted and put into a lay plan. Which can then be sent to the automatic laying and cutting system as a control program. Or, the patterns can be sent to a large plotting device. Where they will be drawn at full scale and used as paper patterns for hand-cutting.

The patterns can also be fed into a machine that cuts templates out of stronger materials automatically.

What Are Grade Specs And Grade Rules?

Grading specifications, also called “grading specs,” are measurements that show how much you want each size to grow or shrink. They are basically telling the factory the same things that your pattern grading rules tell them.

The Grading rule says how much each POM (point of measurement) is made bigger or smaller to fit a wide range of sizes. Its main goal is to make sure that a manufactured garment fits well and has a balanced shape.

How To Create Grade Rules And Grade Specs

Your rule for giving a grade will depend mostly on the style they are making. If you are making athletic clothes, the size pattern should have enough room for movement. For a boxy-shaped garment, each size will need to have extra room to make it fit oversize.

Before you can make grade specs, you will need to measure the sample size. Some of these measurements will come straight from your body measurements. While others will be based on your body measurements plus the garment ease amount.

Some of these basic points of measurement are;

- Full garment length

- Chest

- Waist

- Hip

- Sleeve length

- Neck width

- Front neck drop

- Across shoulder

After you add up your points of measurement, you add the grade rule to figure out which sizes are bigger and smaller based on the sample size you chose.

How To Grade A Pattern Between Sizes

Draw a line between the notches on the pattern where the sizes need to be different. Make sure you change all of your pieces the same way and that the seams still line up after you grade.

Tech pack design is product development software that helps you figure out measurements for all sizes much more quickly. Based on garment measurement you give or your own garment grading rules.

What Is Grading In Fashion Designing Industry

Gradation In fashion design, you do things that give the whole process of making a garment a sense of meaning and purpose.

For example, if you want to use a specific pattern on a wider range of clothing designs. You need to figure out how to use the same pattern on different sizes and shapes of the same clothing design.

Grading pattern helps make a line of clothes that come in different sizes but have the same pattern.

This makes it easier to use certain themes on a wide range of clothes that are different sizes.

A designer needs to know how to grade a pattern in order to make clothes for a fashion line that can fit people with different body types.

How Grading Helps Out Designers

With grading, a good pattern can be sized up or down. Grading also makes it easier to change the size of a pattern as a person’s body changes. Imagine how cool it would be to use grading to keep a child’s favorite dress pattern the same as he or she grows.

-

Using The “Slash And Spread” Method

Before drawing a new pattern, the part of the pattern that needs to be changed is cut in both directions and spread out to the new size of the garment. This is called moving up a grade. When grading down, the cut-out pieces go on top of each other instead of being spread out.

-

By Using The Shift Method

The shape of the pattern piece is moved outward or inward or given extensions. The pattern art is then made again.

CAD software for computer grading makes the whole process go more smoothly. It works great for making patterns, figuring out sizes, and figuring out how much fabric will shrink.

Method For Patterns Making In 5 Easy Steps

Pattern-making is the art of changing a design on a piece of fabric so that it fits a person’s body. The goal of making a pattern is to get a custom fit or a perfect fit. With pattern-making technology, a 2D two-dimensional drawing of the garment being designed is made.

Pattern making is the basis for the whole garment because it shows where the fabric should be cut so that it fits the shape of the customer.

There are different ways to make patterns for clothes, like block pattern printing or computerized pattern making. But the most common way is flat pattern making, which can be done in five easy steps:

-

Collect Your Tools

There are a few special tools that every pattern maker will have. But as time has gone on, pattern makers have added different tools to the process:

-

Erasers And Pencils

The first two things you’ll need when making patterns are a pencil and an eraser. You might find yourself going back to your first designs when you’re making the first draught. This is why even skilled pattern makers don’t use pens or markers.

-

Patterning Paper

It’s different from regular sketching paper because it has lines on it. The length, inches, or sizes can be seen on the paper because it is a graded pattern or marked. It saves time for the people who make things.

-

Flexible Rulers

These are more useful than straight ones because they can be bent into different shapes or angles to measure contours. A good flexible ruler should be at least 65 inches long.

-

The Curve For The Hips And Arms

The hip and arm style curve is the name of a rigid, curved ruler that is used to draw or measure curves and angles after the pattern has been sketched with straight lines.

-

Straight Gridded Rulers

When you need to measure the length, width, or height of your designs, these rulers come in handy. Most of the time, you need two of them. One should be about 6–8 inches long, and the other should be about 13–15 inches long. For precise measurements, the shorter scale is best. However, a larger scale is useful for measuring larger distances.

-

Careful Measurements Of The Body

Patterns are made either to fit a specific need or to fit a standard size. For a perfect fit, the people who make patterns or designs need to take accurate measurements. When making a flat pattern, you need to know your height, waist, bust, waist, arm, rise, and in-seam.

-

Adding Designs And Styles

The first draft of the pattern is made based on the customer’s body size or style. Putting together different styles in your design will make it stand out from other designs and make a fashion statement.

Styles like flared sleeves are added to the original sketch by the people who make patterns. But you should also think about how the clothes fit and how good they look on you.

-

Evaluation Of Your Design

Grading is the process of taking the same basic paper pattern and making it fit different sizes. In customer markets or emergencies where sizes need to be changed quickly, paper grading is the most efficient way to do this because it lets you reduce or increase the size of one template.

Patterning papers are often graded. You can just as easily trace the original pattern on another piece of pattern paper to change the size of the original pattern.

-

Moving On To Draping

After the pattern is drawn on paper, two-dimensional images should be turned into three-dimensional ones so that final changes can be made and to get an idea of how it will look on a body as opposed to a flat surface. When this happens, draping comes into play.

After the pattern is made, it should be drawn on a piece of fabric and stitched together with needles. With the cut-out fabric based on the drawn design, draping shows how a customer wants to look.

Conclusion

It’s one thing to make a garment, but it’s a whole other thing to make sure that it gets worn. Unlike textile makers, who only do manual work, pattern designers are expected to be creative while also doing their administrative work well. This is the sole responsibility of the person who made the pattern and no one else. In the fashion industry, pattern grading is in charge of making sure that designs on paper translate well to fabrics in the real world.